How On-Site Nitrogen Works

The air we breathe is roughly 78% nitrogen and 21% oxygen. By simply taking atmospheric air and compressing it to >100 psig, we can then feed that air to our nitrogen generator. Inside the nitrogen generator (PSA or Membrane) we perform “AIR SEPARATION”. Simply put, we separate (remove) the oxygen from the compressed air stream. What is left is a stream of nitrogen gas to be used for numerous applications including food packaging; laser cutting; laboratory applications; chemical blanketing; etc.

There are two common methods for On-Site Nitrogen Production, membrane and PSA (Pressure Swing Adsorption). With both systems, a source of dry, clean, oil-free compressed air is required. Depending on the size of the nitrogen generator, “house” or “plant” compressed air may be used. In some situations a dedicated air compressor may be required. For applications that can tolerate a higher amount of oxygen, a membrane nitrogen generator maybe better suited. If your process cannot tolerate much oxygen, a PSA (Pressure Swing Adsorption) nitrogen generator is best. Both technologies have the same life cycle, assuming they are maintained as per manufacturer’s specifications for preventive maintenance.

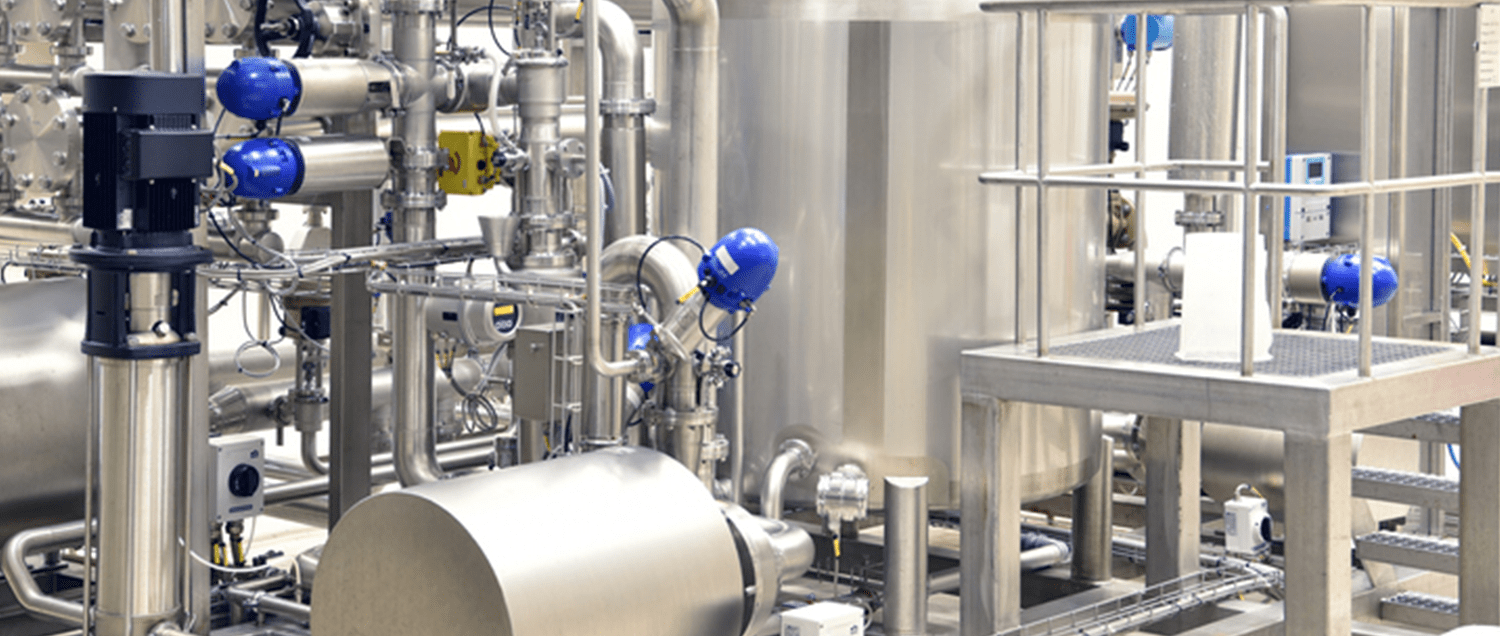

On-Site Nitrogen Production – Membrane Nitrogen Generators

Membrane nitrogen generators use technically advanced hollow fibers to separate oxygen and nitrogen from the compressed air stream. By simply throttling back the flow rate of the air through the membrane module, you can control the air separation process, increasing or decreasing the purity (amount of O2 in the nitrogen stream).

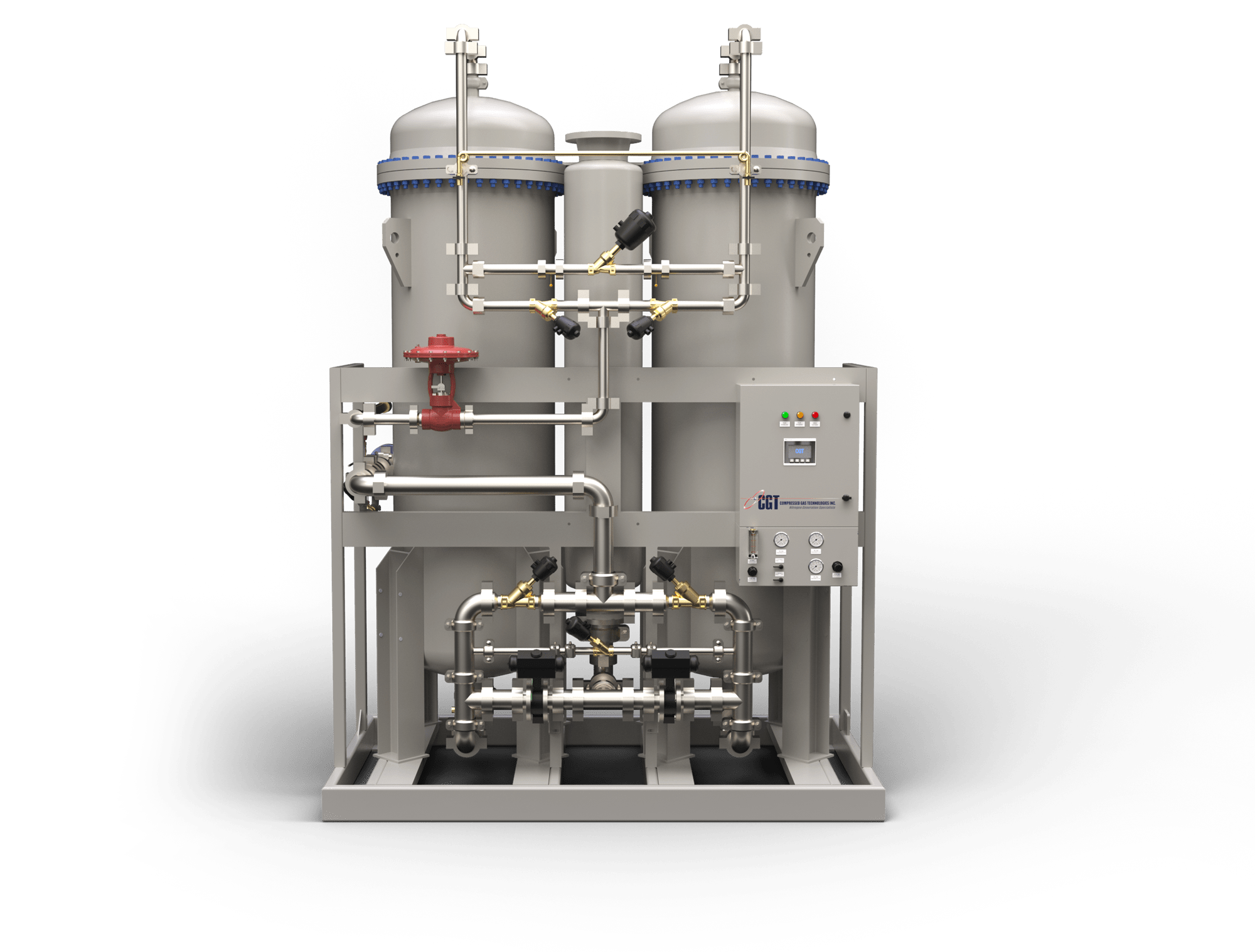

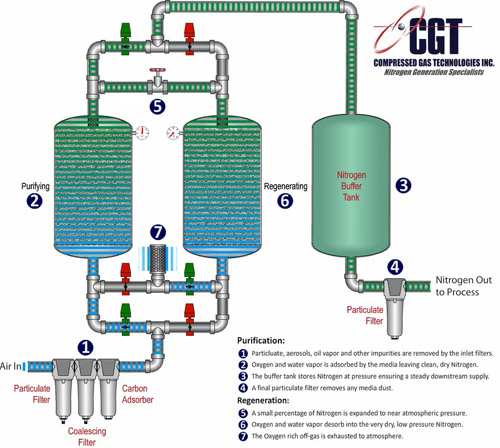

On-Site Nitrogen Production – PSA Nitrogen Generators

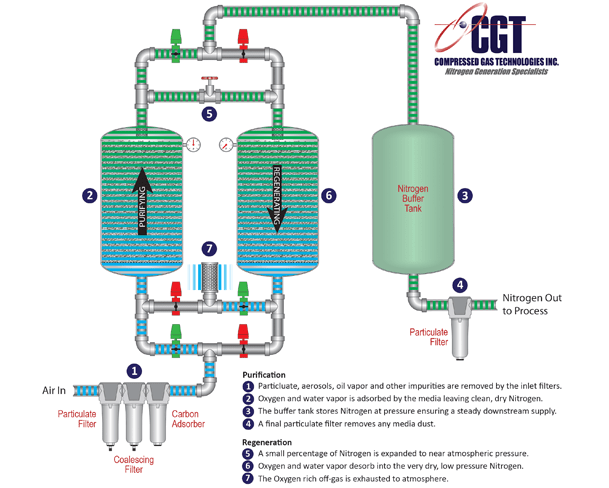

PSA (Pressure Swing Adsorption) nitrogen generators utilize two towers filled with a chemical called carbon molecular sieve (CMS). Compressed air enters one tower, as the air flows through, the oxygen molecules then begin to bond to the CMS under pressure, with the remaining gas being mainly nitrogen. After a set time, the two towers shift back and forth with the air entering the second tower, while the first tower depressurizes venting the oxygen gas to atmosphere. Almost and flow rate and purity can be achieved by utilizing adequately sized towers.

On-going maintenance of nitrogen production units is relatively minor. Compressed air filtration packages must be maintained as per manufacturer’s specification. This will ensure years of trouble-free operation. Typically all service can be done in house by your maintenance staff.

If you have an application that you think may benefit from on-site nitrogen production – please contact us for a quote. If you have further questions regarding on-site nitrogen production – please call us at 1- 877-737-7760 or submit an inquiry here.